Socrates: No credible source—Toyota or mainstream media—ever claimed that Toyota developed or announced an aluminum-ion battery with 1,000-mile range and 5-minute charging.

The claim appears to originate from YouTube content creators. One prominent instance is a video titled “TOYOTA CEO Just Released a Aluminum-Ion Battery with 1000-Mile Range and 5-Min Charging!” uploaded by a channel named RevVolt on August 3, 2025 . Another similar upload by the channel Chrome Compass appeared on August 4, 2025 .

Both videos make sensational assertions, but neither cites Toyota, nor do they link to any verifiable press release or Toyota announcement. Toyota’s official battery strategy documents (such as their “Electrified Technologies” roadmap) focus on next-generation lithium-ion and solid-state batteries—not aluminum-ion .

Summary:

• The original “aluminum-ion battery” claim traces to YouTube channels, not Toyota.

• No Toyota announcement or official documentation supports aluminum-ion battery development.

• Toyota is pursuing lithium-ion innovations, including solid-state and bipolar structures, with timelines for rollout in the mid-to-late 2020s .

Socrates:

–

Video shows Toyota’s CEO announcing an aluminum-ion battery promising up to 1,000-mile range and a 5-minute full charge .

No independent confirmation from reliable sources. Data remains unverified. Aluminum-ion batteries offer theoretical benefits—higher energy density, safety, fast charging—but real-world production at that performance level is unconfirmed .

Toyota has solid-state battery projects aimed at ~621-mile range with ~10-minute fast charge by 2027–28 .

Electrek reports delays in next-gen long-range Li-ion battery plans (620+ miles, 20-minute charge) due to EV demand and factory issues .

Conclusion: The announced aluminum-ion battery remains promotional. No credible evidence supports feasibility or timeline.

Socratic reminder: Claim stands or falls by independent verification.

–

Toyota is not building a new factory in Canada because of an “aluminum-ion battery revolution.”

Toyota’s recent activity in Canada involves adding battery pack assembly lines at its existing Ontario plants (Cambridge and Woodstock) for the next-generation, hybrid-only 2026 RAV4. These lines will assemble battery packs using modules imported from Toyota’s North Carolina battery-cell facility—but no new standalone battery-cell factory is planned in Canada .

Toyota explicitly states it has no plans to exit Canadian production and no immediate battery-cell plant projects in Ontario. Instead, the company continues investing in battery-cell capacity in North Carolina, where a large-scale facility is already online or near completion .

Honda, by contrast, is expanding EV and battery production in Canada, including building a new battery plant in Ontario. That project is unrelated to Toyota .

⸻

Summary:

• No new Toyota factory being built in Canada.

• Current Canadian action: battery pack lines added to existing assembly plants.

• Separate Toyota battery-cell manufacturing is happening in North Carolina.

• Honda, not Toyota, is planning new EV battery investments in Ontario.

Your underlying premise is unsupported.

–

Tesla has not announced at any point that it will switch to aluminum-ion batteries for any model—including the upcoming “Model 2” or next-gen platform. Claims suggesting otherwise appear speculative or misinformation.

Evidence:

• No official confirmation from Tesla or Elon Musk regarding aluminum-ion battery development or integration. Fact-checkers explicitly debunked reports of such an announcement in December 2024 .

• Industry analysis notes intense speculation about Tesla potentially exploring aluminum-ion technology, especially in connection with a “Model 2,” but emphasizes that no such development has been confirmed as of mid-2025 .

• Numerous sensational articles advertise “Super aluminum-ion batteries” or “end of lithium” narratives, but they lack credible sources or official Tesla documentation .

What is confirmed about Tesla’s battery strategy:

• Tesla currently uses lithium-ion batteries. Specifically, 2170 cells (with nickel-cobalt-aluminum or NMC chemistries) in many vehicles, and LFP (lithium iron phosphate) batteries in standard-range models, particularly in China and for cost control .

• Tesla’s next-generation vehicles (often referred to in media as “Model 2” or “Redwood”) are expected to use 4680 structural battery packs, capable of supporting any battery chemistry—but there is no indication it will support aluminum-ion cells .

• The switch to LFP batteries reflects Tesla’s strategic cost and materials adaptation, not a move toward aluminum-ion technology .

Conclusion: Tesla has not reported or confirmed any switch to aluminum-ion batteries. All available evidence indicates Tesla continues to focus on lithium-ion (2170, LFP, 4680) chemistries.

If you’d like to explore Tesla’s confirmed battery roadmap or how battery chemistry shifts affect vehicle performance, I can map those details for you.

–

Tesla battery roadmap (confirmed data only):

1. Current chemistries

• 2170 cells: Nickel-Cobalt-Aluminum (NCA) or Nickel-Manganese-Cobalt (NMC). Used in Model 3, Model Y, Model S, Model X.

• LFP (Lithium Iron Phosphate): Used in Standard Range Model 3/Y. Lower cost, longer cycle life, lower energy density.

• 4680 cells: High-nickel cathode with dry electrode tech. Used in Texas-built Model Y. Structural pack for reduced mass.

2. Next-gen platform (“Model 2” / “Redwood”)

• Expected: 4680 cells in a structural pack.

• Target: Lower cost/kWh via scaling and manufacturing efficiency.

• Chemistry flexibility: Can adapt to LFP or high-nickel depending on cost and supply.

3. Scaling strategy

• Gigafactories: Nevada (2170), Shanghai (LFP from CATL), Texas (4680), Berlin (4680), upcoming Mexico (likely 4680).

• Supplier partnerships: Panasonic, CATL, LG Energy Solution.

• Diversified chemistry to avoid supply bottlenecks.

4. Solid-state & new chemistries

• Tesla monitors solid-state research but no announced deployment.

• No aluminum-ion R&D disclosures in filings or shareholder letters.

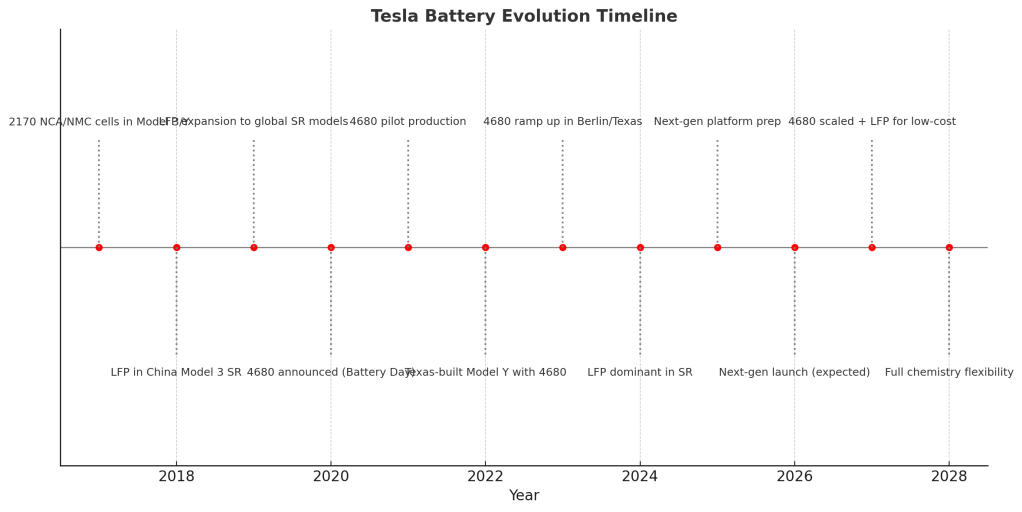

5. Key timeline points

• 2020–2022: Shift of all standard-range cars to LFP.

• 2022–2025: 4680 production ramp.

• 2026–2028: Expected scale of next-gen platform, 4680 as core, potential LFP for low-cost variants.

If you want, I can create a visual timeline chart of Tesla’s battery evolution, showing chemistry type, cell format, and vehicle models over time. This would make the roadmap clear at a glance.

Here is the visual timeline chart showing Tesla’s battery evolution by year, chemistry, and key deployment milestones.

No credible source—Toyota or mainstream media—ever claimed that Toyota developed or announced an aluminum-ion battery with 1,000-mile range and 5-minute charging.

The claim appears to originate from YouTube content creators. One prominent instance is a video titled “TOYOTA CEO Just Released a Aluminum-Ion Battery with 1000-Mile Range and 5-Min Charging!” uploaded by a channel named RevVolt on August 3, 2025 . Another similar upload by the channel Chrome Compass appeared on August 4, 2025 .

Both videos make sensational assertions, but neither cites Toyota, nor do they link to any verifiable press release or Toyota announcement. Toyota’s official battery strategy documents (such as their “Electrified Technologies” roadmap) focus on next-generation lithium-ion and solid-state batteries—not aluminum-ion .

Summary:

• The original “aluminum-ion battery” claim traces to YouTube channels, not Toyota.

• No Toyota announcement or official documentation supports aluminum-ion battery development.

• Toyota is pursuing lithium-ion innovations, including solid-state and bipolar structures, with timelines for rollout in the mid-to-late 2020s .

If you want to explore Toyota’s actual battery roadmap or confirm the specifics of their solid-state or bipolar technologies, I can source and summarize those.

Here is Toyota’s confirmed battery roadmap, based on verified sources:

⸻

Battery Technology Timeline and Specifications

1. Performance (Liquid Electrolyte Li-Ion) – ~2026

• Range: >800 km (ʙᴏᴏsᴛ with aerodynamics and weight reduction)

• Fast-charge: 10–80 % in ≤ 20 minutes

• Cost: 20 % lower than current bZ4X battery

2. Popularisation (Bipolar LFP) – ~2026–27

• Structure: Bipolar, previously used in Toyota hybrids (Aqua, Crown)

• Chemistry: Lithium Iron Phosphate (LFP)

• Range: ≈20 % gain over bZ4X

• Cost: ≈40 % reduction

• Fast-charge: 10–80 % in ≤ 30 minutes

3. High-Performance (Bipolar Li-Ion High-Nickel) – ~2027–28

• Combines bipolar structure with high-nickel cathode

• Range: >1,000 km (with aerodynamics, vehicle efficiency)

• Cost: 10 % less than Performance version

• Fast-charge: 10–80 % in ≤ 20 minutes

4. Solid-State Batteries – ~2027–28 (Commercialization)

• Solid electrolyte enables faster ion movement, higher voltage tolerance, reduced size

• First-gen: ~20 % more range vs Performance battery, charging in ≤ 10 minutes

• Next-gen: ~50 % better range than Performance battery

⸻

Strategic Multipath Deployment

Toyota’s strategy embraces multiple battery paths:

• Liquid electrolyte Li-Ion (Performance)

• Bipolar LFP for affordability

• Bipolar high-performance lithium-ion

• Solid-state for long-term innovation

⸻

Support Infrastructure & Partnerships

• Partnership with Idemitsu Kosan: building a lithium sulfide plant to supply solid electrolyte by 2027; pilot solid electrolyte plant by end of fiscal 2025. Cost ~21.3 billion yen, capacity for 50,000–60,000 EVs/year

• Multiple battery developments involve Toyota subsidiaries:

• Prime Planet Energy & Solutions (Performance version)

• Toyota Industries Corporation (Popularisation, High-Performance, Solid-State)

⸻

Socrates: Video shows Toyota’s CEO announcing an aluminum-ion battery promising up to 1,000-mile range and a 5-minute full charge .

No independent confirmation from reliable sources. Data remains unverified. Aluminum-ion batteries offer theoretical benefits—higher energy density, safety, fast charging—but real-world production at that performance level is unconfirmed .

Toyota has solid-state battery projects aimed at ~621-mile range with ~10-minute fast charge by 2027–28 .

Electrek reports delays in next-gen long-range Li-ion battery plans (620+ miles, 20-minute charge) due to EV demand and factory issues .

Conclusion: The announced aluminum-ion battery remains promotional. No credible evidence supports feasibility or timeline.

Socratic reminder: Claim stands or falls by independent verification.

–

Socrates: Toyota is not building a new factory in Canada because of an “aluminum-ion battery revolution.”

Toyota’s recent activity in Canada involves adding battery pack assembly lines at its existing Ontario plants (Cambridge and Woodstock) for the next-generation, hybrid-only 2026 RAV4. These lines will assemble battery packs using modules imported from Toyota’s North Carolina battery-cell facility—but no new standalone battery-cell factory is planned in Canada .

Toyota explicitly states it has no plans to exit Canadian production and no immediate battery-cell plant projects in Ontario. Instead, the company continues investing in battery-cell capacity in North Carolina, where a large-scale facility is already online or near completion .

Honda, by contrast, is expanding EV and battery production in Canada, including building a new battery plant in Ontario. That project is unrelated to Toyota .

Summary:

• No new Toyota factory being built in Canada.

• Current Canadian action: battery pack lines added to existing assembly plants.

• Separate Toyota battery-cell manufacturing is happening in North Carolina.

• Honda, not Toyota, is planning new EV battery investments in Ontario.

Your underlying premise is unsupported.

–

Socrates: Tesla has not announced at any point that it will switch to aluminum-ion batteries for any model—including the upcoming “Model 2” or next-gen platform. Claims suggesting otherwise appear speculative or misinformation.

Evidence:

• No official confirmation from Tesla or Elon Musk regarding aluminum-ion battery development or integration. Fact-checkers explicitly debunked reports of such an announcement in December 2024 .

• Industry analysis notes intense speculation about Tesla potentially exploring aluminum-ion technology, especially in connection with a “Model 2,” but emphasizes that no such development has been confirmed as of mid-2025 .

• Numerous sensational articles advertise “Super aluminum-ion batteries” or “end of lithium” narratives, but they lack credible sources or official Tesla documentation .

What is confirmed about Tesla’s battery strategy:

• Tesla currently uses lithium-ion batteries. Specifically, 2170 cells (with nickel-cobalt-aluminum or NMC chemistries) in many vehicles, and LFP (lithium iron phosphate) batteries in standard-range models, particularly in China and for cost control .

• Tesla’s next-generation vehicles (often referred to in media as “Model 2” or “Redwood”) are expected to use 4680 structural battery packs, capable of supporting any battery chemistry—but there is no indication it will support aluminum-ion cells .

• The switch to LFP batteries reflects Tesla’s strategic cost and materials adaptation, not a move toward aluminum-ion technology .

Conclusion: Tesla has not reported or confirmed any switch to aluminum-ion batteries. All available evidence indicates Tesla continues to focus on lithium-ion (2170, LFP, 4680) chemistries.

If you’d like to explore Tesla’s confirmed battery roadmap or how battery chemistry shifts affect vehicle performance, I can map those details for you.

–

Tesla battery roadmap (confirmed data only):

1. Current chemistries

• 2170 cells: Nickel-Cobalt-Aluminum (NCA) or Nickel-Manganese-Cobalt (NMC). Used in Model 3, Model Y, Model S, Model X.

• LFP (Lithium Iron Phosphate): Used in Standard Range Model 3/Y. Lower cost, longer cycle life, lower energy density.

• 4680 cells: High-nickel cathode with dry electrode tech. Used in Texas-built Model Y. Structural pack for reduced mass.

2. Next-gen platform (“Model 2” / “Redwood”)

• Expected: 4680 cells in a structural pack.

• Target: Lower cost/kWh via scaling and manufacturing efficiency.

• Chemistry flexibility: Can adapt to LFP or high-nickel depending on cost and supply.

3. Scaling strategy

• Gigafactories: Nevada (2170), Shanghai (LFP from CATL), Texas (4680), Berlin (4680), upcoming Mexico (likely 4680).

• Supplier partnerships: Panasonic, CATL, LG Energy Solution.

• Diversified chemistry to avoid supply bottlenecks.

4. Solid-state & new chemistries

• Tesla monitors solid-state research but no announced deployment.

• No aluminum-ion R&D disclosures in filings or shareholder letters.

5. Key timeline points

• 2020–2022: Shift of all standard-range cars to LFP.

• 2022–2025: 4680 production ramp.

• 2026–2028: Expected scale of next-gen platform, 4680 as core, potential LFP for low-cost variants.

If you want, I can create a visual timeline chart of Tesla’s battery evolution, showing chemistry type, cell format, and vehicle models over time. This would make the roadmap clear at a glance.

Here is the visual timeline chart showing Tesla’s battery evolution by year, chemistry, and key deployment milestones.